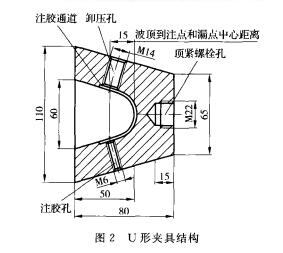

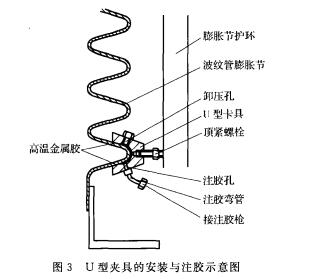

It is difficult to make the contact surface in U - shaped fixture. In order to make the U clamp and does not produce too much space between the corrugated pipe, to ensure that the glue injection effect, we use the setting-out measure U face of fixture design and processing, at the same time will and good dough, paste in the leak, after being dry forming, and to make the mould, then according to the shape of mold inside condition, make jig. This work is very professional, usually by the technical hard, hand live good fitter to complete, because the temperature of the medium is very high, the metal glue directly bonding strength is very low, the design of the fixture must firmly clamp leakage point. According to the location of the leakage point and the shape of the bellows of expansion joint, we designed a u-shaped fixture with a width of 50 m. The u-shaped fixture is equipped with glue injection hole, glue injection channel, pressure relief hole and bolt hole. Injection hole, pressure relief hole and jacking bolt hole are designed to be the choice of sealant for internal thread connection hole

jig

(l) first choose adhesive. Since the temperature of leaking medium is as high as 670C, consider the temperature and the composition of the medium and the material of the bellows. According to these two points, we choose m-m-1 type of high strength heat resistant inorganic adhesive imported from Germany. This adhesive is more suitable for the low-pressure sealing of high-temperature pipelines, and can be used under the temperature of 70 O C. There are two kinds of materials that are evenly mixed according to the quality ratio of 1,1, and used up within 30 minutes after being harmonized.

(2) selection of glue injection sealant. Since the glue injection mouth is at the lower part of the expansion joint, which is far away from the leakage point, and the glue injection flow channel of the fixture is relatively narrow, it is necessary to choose the sealant with good liquidity. After screening, we choose tianjin xiangyue T X Y 1 no. 16 high-temperature sealant.

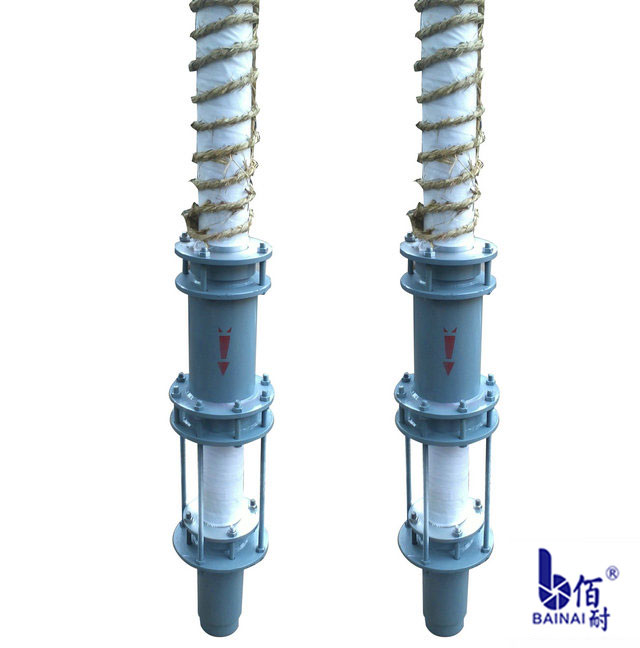

Blocking diagram

3. Implementation of plugging

(1) as the leakage point anomaly of expansion joint is 4 m high, check the constructed shelves before construction. The shelves should be reliable and qualified before the leakage plugging construction.

(2) the leakage points belong to high temperature operation, difficult construction, must strictly implement relevant security rules, the work high above the fasten your seat belt, wear a good helmet correctly, need to wear during the construction of the aluminum foil heat insulation clothing and aluminum foil heat insulation gloves, operating personnel on a shelf construction cannot be more than two people, to coordinate each other, set personnel monitoring platform, ensure the safety of construction personnel.

(3) construction will first high temperature metal adhesive coating in the u-shaped clamp and the inner surface of the expansion joint bellows contact, to prevent installing a u-shaped clamp, metal rubber and leakage of flue gas blowing out in the metal rubber also there is no cure, and will have certain strength, as in u-shaped clamp installed to the leak position of the expansion joint bellows, at the same time, the pressure relief hole must be accurately on the leakage point, make the flue gas by pressure relief hole pressure relief, to ensure that the metal adhesive before fully cured not blown away by flue gas, ensure adhesive sealing performance and results. In this way, the u-shaped fixture is glued to the expansion joint to ensure the sealing effect during glue injection.

(4) in order to ensure the jig inside and expansion joint leak tight, prevent leakage of flue gas with certain pressure, make U jig firmly on the bellows, we use expansion joint ring will clamp on the corrugated pipe, as shown in figure 3, the method is on the other side of the jig making silk, high temperature adhesive coating on fixture during the construction of the medial, with top silk top tight after use of expansion joint sheath with a screw to clamp the top. The problem of fixture fixing lays a foundation for the bottom plugging.

(5) before glue injection, apply sealant to the thread of M 14 single-head bolt and wear protective gloves to seal the pressure relief hole quickly. Conduct observation and proceed to the next process construction after there is no problem.

(6) the construction space is narrow and the construction is difficult. The leakage point is at the upper part of the wave peak, and the distance between the expansion joint retaining ring and the wave peak is only 100mm, and the height of the retaining ring is 340m from the leakage point, so it is impossible to directly inject glue to the leakage point from the upper part, and the glue gun cannot be installed on the fixture. We have considered this problem in the design of fixture, so in the bottom of the injection hole for injection.

(7) there is a groove between the pressure relief hole and the glue injection hole on the upper part of the u-shaped fixture, through which the glue solution is injected to the leakage site. When the glue injection gun is directly connected at the position of the glue injection hole, the distance between the guard ring and the bellows is relatively close, and the glue injection gun cannot extend inside. Therefore, an 8 m thick stainless steel elbow pipe is added to connect the glue injection gun

(8) during glue injection, because the high-temperature rubber material hardening very quickly, in order to prevent premature hardening of the rubber material at high temperature, it cannot be injected to the leakage point. During glue injection, cooling method of fixture shall be adopted to ensure the smooth arrival of the rubber material to the leakage point for sealing. In addition, because the bellows are relatively thin, only 2.5mm, can not use the conventional injection pressure calculation method, but use the field observation method for injection, injection to no leakage will immediately stop, so as not to play the bellows deformation accident.