In the process of boiler combustion, the air required for combustion must be continuously sent into the furnace and the combustion products out at the same time, so that the process of continuous air supply and the elimination of combustion products is called the ventilation process of the boiler. The balanced ventilation, it is proposed that used in boiler smoke duct blower, draught fan, a fan device, use blower to overcome the resistance of boiler air duct system, induced draft fan is used to overcome the resistance of the flue system, using a fan main overcome resistance in the coal pulverizing system, and to keep the furnace exit certain negative pressure. Its advantage is that all the flue of the boiler work under the negative pressure, the safety and health conditions of the boiler room is better, compared with the negative pressure ventilation, its flue negative pressure is smaller, less air leakage.

This type of ventilation may also be called forced ventilation because the balanced ventilation is provided with a blower, an induced draft fan and a primary fan. In order to reduce the air pollution in the nearby area, chimneys must be built at a certain height when forced ventilation is carried out, in order to discharge the ash particles and harmful gases in the smoke into the upper air.

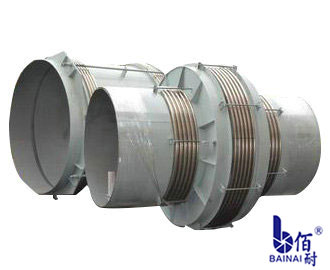

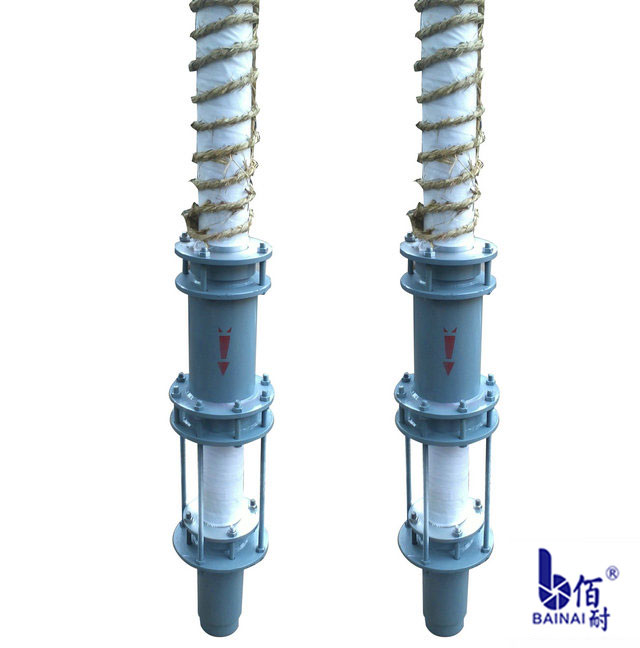

It can be seen that the smoke air system consists of cold air duct, hot air duct, induced draft fan, primary fan, steam boiler tail flue, chimney, flue and dust collector. The smoke duct principle system diagram shown below can be used.

Two streams of air pass through the air preheater at the same time, one part enters the coal mill and then transfers fuel into the furnace, the other part enters the burner nozzle directly as a secondary air. In addition, in the intermediate storage type pulverizing system, the recycling tube bundle is used to coordinate the air volume required in three aspects of coal grinding, drying and combustion: part of the spent coal grinding gas is returned to the coal grinding machine from the pulverizing fan, and then to the pulverizing machine for recycling. This can not only reduce the desiccant temperature at the entrance of coal mill, increase the air flow of coal mill, but also give consideration to the requirement of primary air required by combustion, and coordinate the air flow of coal mill and primary air flow.